Quality Control

Our commitment to quality is evident in our inspection processes, which guarantee product integrity and compliance with UL, CSA, and other regulatory standards, making RMC the trusted choice for hygienic stainless raceway systems.

Testing Process

Our comprehensive testing procedures begin when raw materials arrive at our facility and continue through to the packaging of the final product.

Our expert team conducts rigorous assessments to ensure that only the highest-quality conduit products makes it to our customers.

With these practices, we deliver conduit solutions that you can trust for reliability, performance, and durability.

Continuous Testing

Thorough Material Evaluation

All materials are carefully inspected to ensure they meet stringent quality benchmarks.

Precision Testing

Our in-house laboratory conducts advanced testing to confirm durability, accuracy, and compliance with industry standards.

Continuous Supervision

Every stage of production is monitored to guarantee consistency and excellence.

Comprehensive Reporting

Detailed documentation is maintained to provide full transparency and traceability.

Our Stainless Testing Includes:

Moisture Resistance Test

We guarantee the durability and reliability of our stainless steel fittings through rigorous high-pressure water testing.

This ensures leak-proof performance, superior corrosion resistance, and long-term dependability, meeting the high standards of demanding environments like food and beverage processing facilities.

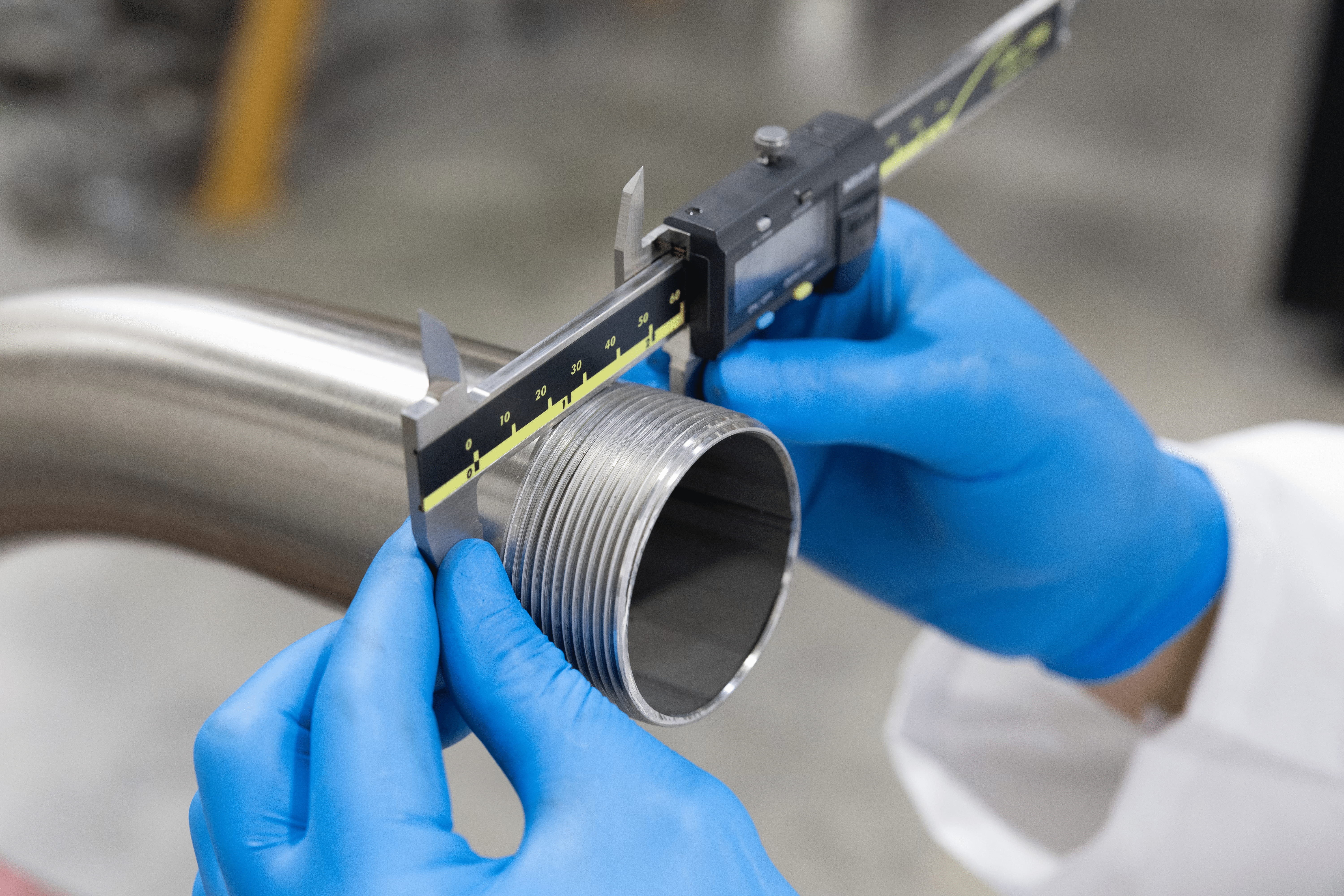

Thread Gauge Test

The thread gauge test on conduit involves checking the accuracy of the threads to ensure proper fit and alignment during assembly.

The thread gauge test on conduit is crucial for maintaining the integrity and reliability of connections to couplings and conduit fittings.

Dimensional Test

Dimensional testing is crucial for meeting ANSI (American National Standards Institute) standards because it ensures that manufactured products adhere to specific dimensional requirements.

By ensuring that products conform to specified dimensions, Rep Materials Co can maintain high-quality standards and minimize the risk of defects or failures.

Degree of Bend Test

A digital angle gauge provides accurate angle measurements using electronic sensors.

On larger segments and elbows, a template or jig is used to ensure consistency and accuracy in bend angles.

Rep Materials is dedicated to ensuring precise bend angles, facilitating efficient and precise field installations.

Production Bend Test

Proper conduit bending is essential for the safe and efficient operation of electrical systems. Inaccurate or poor-quality bends can lead to system inefficiencies, increased maintenance costs, and potential safety hazards.

Surface Smoothness Inspection

Rep Materials Co. inspects all stainless steel conduit and fittings for surface smoothness, eliminating imperfections that could harbor contaminants.

Our precision checks ensure consistent, hygienic surfaces that resist bacterial buildup and facilitate cleaning—meeting critical requirements for food processing and other demanding applications.

Assembly Test

Rep Materials Co. conducts comprehensive assembly testing to ensure the flawless performance of our stainless steel fittings.

RMC’s fittings undergo rigorous inspection and testing to ensure precise thread engagement, secure compression rings, and properly fitted sealing gaskets, delivering a leak-proof and dependable connection. This rigorous quality control process ensures that every fitting meets strict industry standards for strength, corrosion resistance, and hygienic design.